xTool S1 and PCB

07.02.26

Circuits

Steps to follow to make PCB

We're not etching a PCB with the xTool laser, but we're transfering the design. Start by cleaning the copper clad board thoroughly with aceton. Then apply a thin layer with acrylic paint. I'm using an airbrush.

These are the steps:

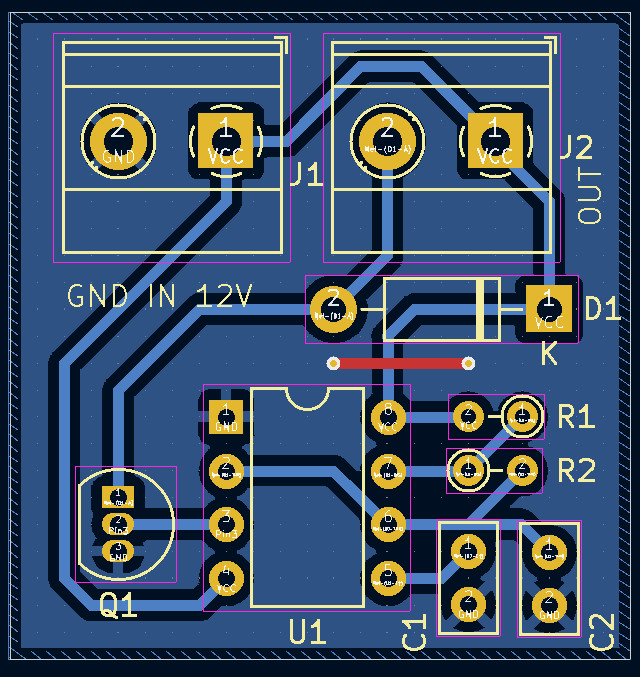

Design the PCB in your favourite eCAD software. I'm using KiCAD

Click on image to enlarge.

The board design.

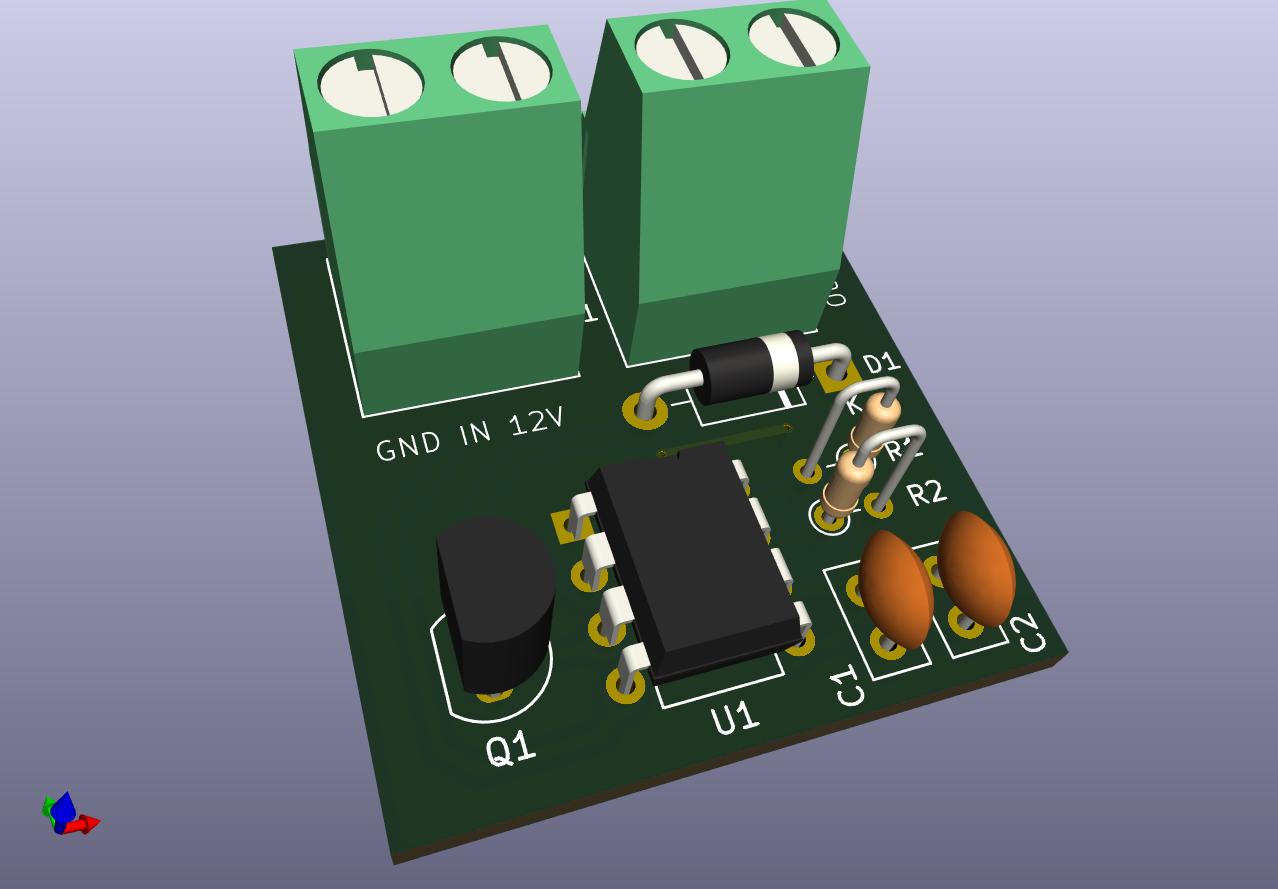

3D view - a nice feature in KiAD

Print the board with these settings:

Include layers: B.CU, Edge.Cuts.

Outputmode: Black and white

Drill marks: Small mark.

Check Print mirrored. (Bottom copper => Mirrored.)

Scale 1:1

Print to a PDF - file.

Import board in Gimp.

File=>Open=>your pdf

Open Pages as Image.

Click Image => Crop to Content.

Click Colours => Invert

Export as... and export the file.

Import the PDF image in xTool Studio.

xTool S1 settings:

Power: 30%.

Speed: 250mm/s.

Pass: 1.

Bitmap mode: Grayscale.

Lines pr cm: 300.

Engraving mode: Bi-directional.

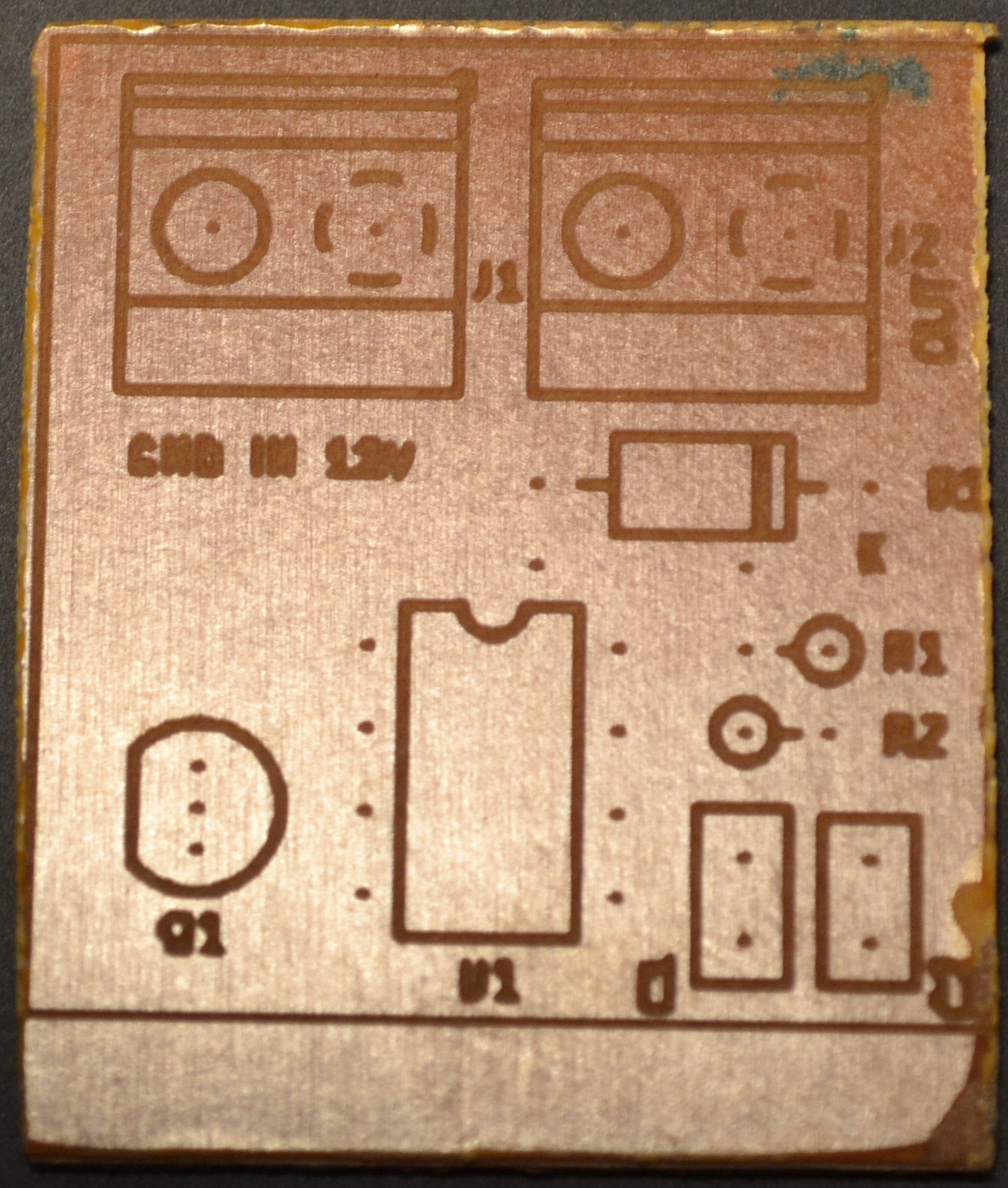

After laser engraving.

Now it's time for the Silkscreen.

Print these layers:

F.Silkscreen.

Edge.Cuts.

Black and white.

Scale: 1:1.

This is the top layer, so it must not be printed mirrored.

xTool settings for the F.Silkscreen.

Power: 25%.

Speed: 250 mm/s.

Pass: 1.

Bitmap mode: Greyscale.

Lines pr cm: 180.

Engraving mode: Bi-directional.

Back